Cedar

Cedar has been used for centuries as an exterior building product. Cedar is exceptionally durable and acts as a natural layer of insulation on your roof/siding, leading to an increase in the energy efficiency of your home. In addition, it also has an exquisite natural beauty that other roofing systems are lacking.

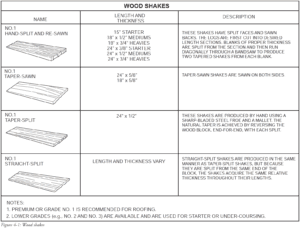

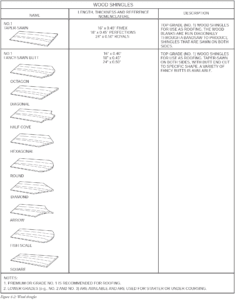

Types of Cedar Shingles / Shake

Images are courtesy of NRCA.

Pressure/Fire Treated

Roofing shakes and shingles made from naturally durable wood species, such as western red cedar, have some degree of resistance to deterioration brought about by exposure to exterior elements.

Preservative-treated roofing shakes and shingles of naturally durable wood or other wood species have an enhanced level of resistance to deterioration in service environments. These products are ideal for areas of high humidity.

Fire-retardant-treated (FRT) wood roofing shakes and shingles offer a degree of permanent fire resistance, which can qualify them for a fire-resistance rating as a part of a roof assembly in accordance with ASTM E108 or UL 790 standard. Treated wood shake and shingle materials are available either as preservative-treated or FRT products. The two types of wood treatments are different and not currently available as one treatment. Treatment companies can be consulted for treatment warranty information; accessory product requirements, including recommended fastener type; and application details for preservative-treated and FRT wood shakes and wood shingles.

Excerpt from NRCA 2017 Roof Manual.

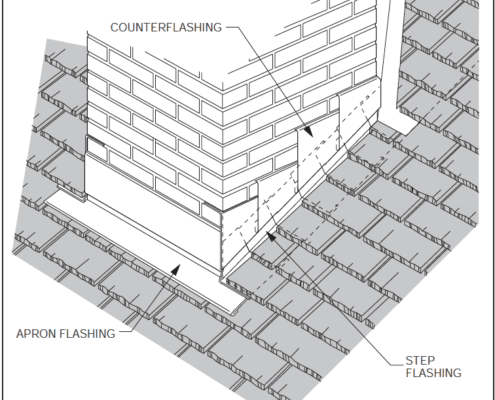

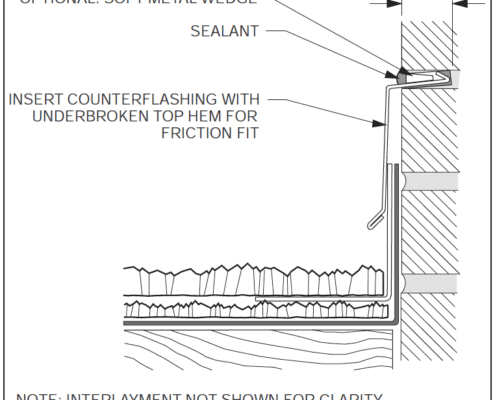

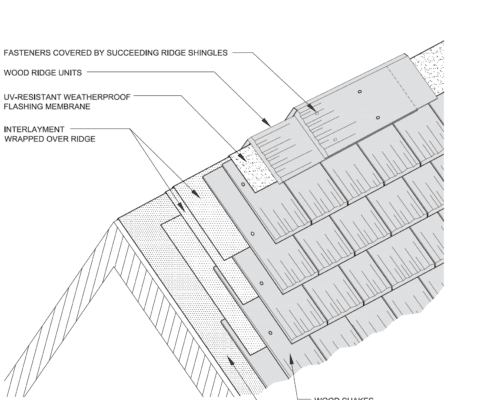

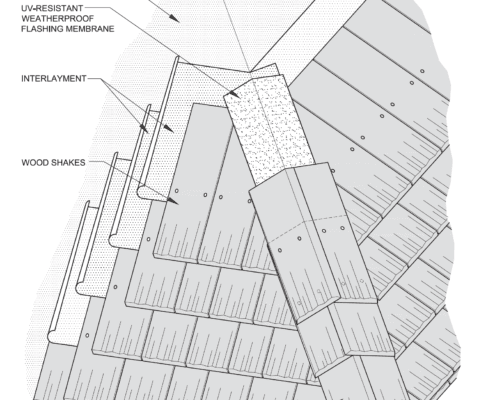

Flashing

- Standard Cedar Roof Anatomy

- Interwoven Felt

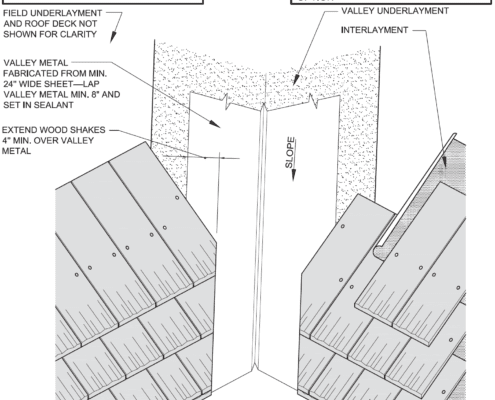

- Cedar Open Valley

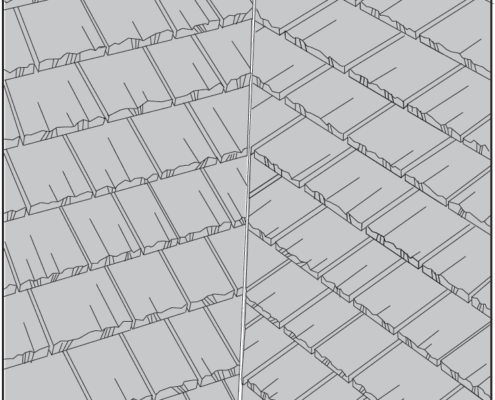

- Cedar Closed Valley

- Cedar Swept Valley

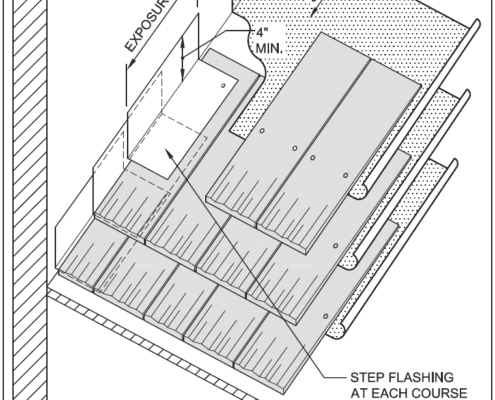

- Cedar Step Flashing

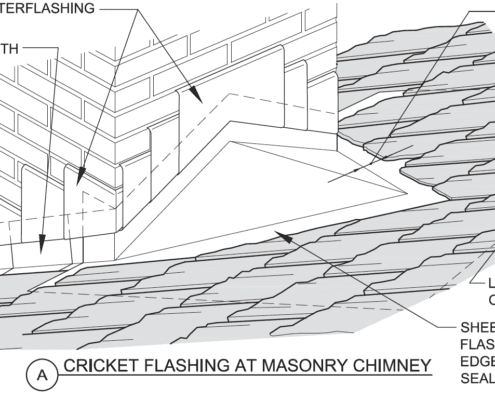

- Cedar Counter Flashing Chimney

- Reglet

- Cedar Ridge

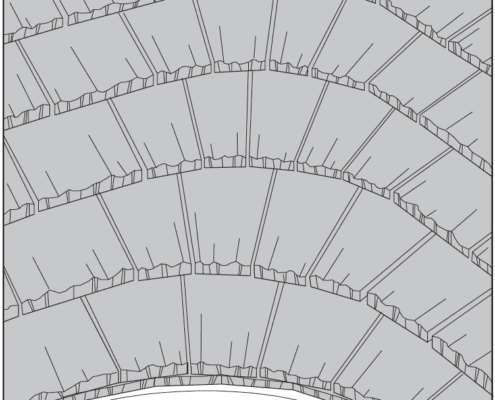

- Cedar Hip

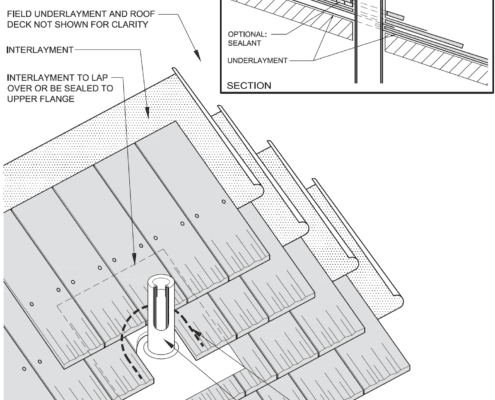

- Cedar Penetrations

- Cedar Roof Chimney Saddle

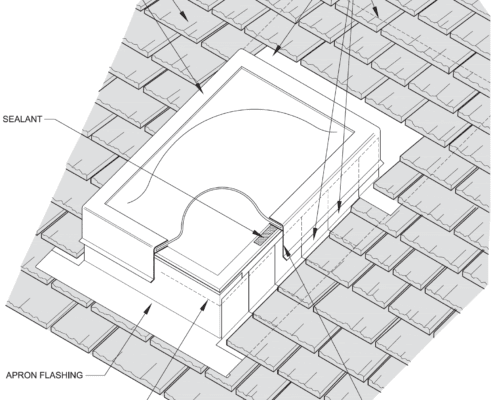

- Cedar Roof Skylight

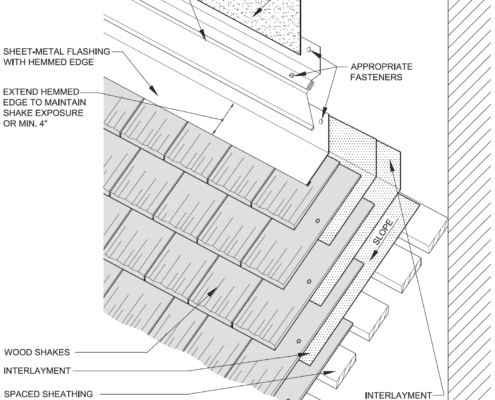

- Cedar Roof to Wall

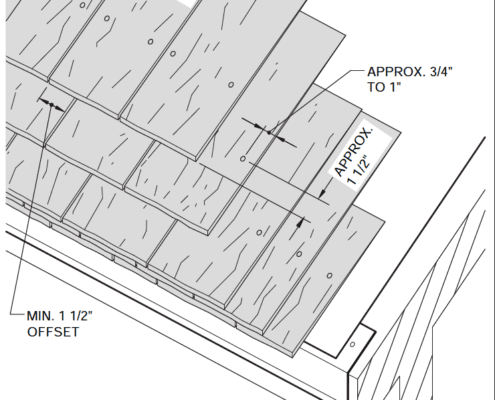

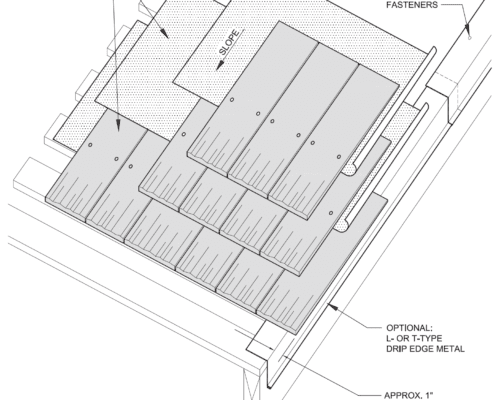

Images are courtesy of NRCA.

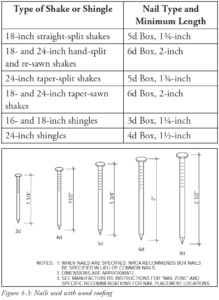

Fasteners

Images are courtesy of NRCA.

The minimum required fasteners for cedar roofs are hot-dipped galvanized steel nails, the next best is Type 304 Stainless Steel, then the premium option is Type 316 Stainless Steel. Type 316 will last the longest and are our preferred fasteners for cedar roofing. Type 316 is mandatory for either pressure treated of fire treated, type 304 was thought to be acceptable with pressure/fire treated in the past, but those standards have changed due to the recent finding that the chemicals used in pressure/fire treatment can corrode Type 304. Hot dipped galvanized should never be used with treated cedar.